|

Shandong Dongyue Building Machine Co.,Ltd

|

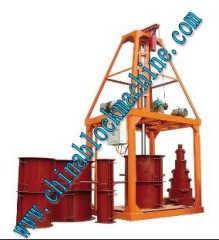

automatic brick making machine

| Price: | 15000.0~17500.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

automatic brick making machine

automatic block machine

block forming mahine

Siemens motor Ormon PLC

China well-known trade

Automatic brick making machine, hollow block machine, baking-free block machine, paver block machine, color brick machine, interlock block making machine, curbstone block machine.

Automatic brick making machine QT4-15C can produce various hollow block, solid bricks, color/paver blocks, and curbstone blocks, etc. QT4-15C adopts the platform vibration; meanwhile the upper mould is pressed by the two hydro-cylinders.

Automatic brick making machine QT4-15C uses international brand-name Germany Siemens motors and Japan Mitsubishi PLC, the limit switch is Omron brand, reliable quality, low fault rate and durable. The material of whole frame for this brick making machine is national standard steel, with high strength and reliable quality.

Automatic brick making machine QT4-15C can produce various hollow block, solid bricks, color/paver blocks, and curbstone blocks, etc. QT4-15C adopts the platform vibration; meanwhile the upper mould is pressed by the two hydro-cylinders.

Automatic brick making machine QT4-15C uses international brand-name Germany Siemens motors and Japan Mitsubishi PLC, the limit switch is Omron brand, reliable quality, low fault rate and durable. The material of whole frame for this brick making machine is national standard steel, with high strength and reliable quality.

All moulds of this automatic brick making machine are processed in high temperature, can work 80000-100000 times without losing shape.

Feeding system: this automatic brick making machine adopts 360°feeding system, can finish feeding materials one time, saving much time, and ensure the density of blocks.

All our products have got ISO9001,CE and SGS certification.

Production capacity: Automatic brick making machine QT4-15C can produce hollow blocks (400*200*200mm) 4pcs/mold, 600pcs/h, paver blocks (200*100*60mm)16pcs/mould, 1820pcs/h, and the solid bricks (240*115*53mm) 30pcs/mould, 5400pcs/h.

Theoretical workshop area: 200 square meters, need about 7-10 workers. The office, curing area,stacking area are arranged according to your specific conditions.

Feeding system: this automatic brick making machine adopts 360°feeding system, can finish feeding materials one time, saving much time, and ensure the density of blocks.

All our products have got ISO9001,CE and SGS certification.

Production capacity: Automatic brick making machine QT4-15C can produce hollow blocks (400*200*200mm) 4pcs/mold, 600pcs/h, paver blocks (200*100*60mm)16pcs/mould, 1820pcs/h, and the solid bricks (240*115*53mm) 30pcs/mould, 5400pcs/h.

Theoretical workshop area: 200 square meters, need about 7-10 workers. The office, curing area,stacking area are arranged according to your specific conditions.

Technical Parameters:

Dimension 2440*2000*2600mm

Pallet size 1010*550*25mm

Vibration form Platform

Molding time 15-25s

Vibration force 40KN

Vibration frequency 4500-5100r/min

Host machine power 29.3KW

Capacity 41.4KW

Rated pressure 25MPa

Working pressure 18-20Mpa

Rated voltage 380V

Weight of host machine 5T

General water Consumption 4T/day

The main features:

A: Computer PLC control system, which can realize the automation production.

B: the four poles orientation means and ultra-long guide bearing, to ensure the pressure head and tooling accurate motion

C: the body with super sections and special welding technology and materials manufacturing, strong vibrationresistant

D: fast mould replacement, can produce road brick, road-edge stone, hollow blocks, standard brick different specifications shapes of cement products multi-usage

E: imported seal, some hydraulic components, equipment comprehensive performance is stable and reliable

F: motor adopts nation inspection-exempted motor (pure TongXin), oil top USES a large-scale hydraulic machinery for oil crest

G: mechanical transmission, compact structure, convenient maintenance, flexible operation, good reliability

H: that pressurize strong rammer, especially and production of high strength concrete-block (bearing heavy intensity can reach 20MPa)

I: finished high strength, good appearance, size precise compactness, shape rules, without burr, drop horn.

J: it can reach high benefit of adding fly-ash, cinders, and various waste residue

K: small investment, quick results

Pallet size 1010*550*25mm

Vibration form Platform

Molding time 15-25s

Vibration force 40KN

Vibration frequency 4500-5100r/min

Host machine power 29.3KW

Capacity 41.4KW

Rated pressure 25MPa

Working pressure 18-20Mpa

Rated voltage 380V

Weight of host machine 5T

General water Consumption 4T/day

The main features:

A: Computer PLC control system, which can realize the automation production.

B: the four poles orientation means and ultra-long guide bearing, to ensure the pressure head and tooling accurate motion

C: the body with super sections and special welding technology and materials manufacturing, strong vibrationresistant

D: fast mould replacement, can produce road brick, road-edge stone, hollow blocks, standard brick different specifications shapes of cement products multi-usage

E: imported seal, some hydraulic components, equipment comprehensive performance is stable and reliable

F: motor adopts nation inspection-exempted motor (pure TongXin), oil top USES a large-scale hydraulic machinery for oil crest

G: mechanical transmission, compact structure, convenient maintenance, flexible operation, good reliability

H: that pressurize strong rammer, especially and production of high strength concrete-block (bearing heavy intensity can reach 20MPa)

I: finished high strength, good appearance, size precise compactness, shape rules, without burr, drop horn.

J: it can reach high benefit of adding fly-ash, cinders, and various waste residue

K: small investment, quick results

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Automatic Brick Making Machines

Automatic Brick Making Machinery

Brick Making Machine

Cement Brick Making Machine

Concrete Brick Making Machine

Clay Brick Making Machine

More>>