|

Shandong Dongyue Building Machine Co.,Ltd

|

brick production line

| Price: | 54000.0~76000.0 USD |

| Payment Terms: | T/T,L/C, T/T,L/C, T/T,L/C, T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

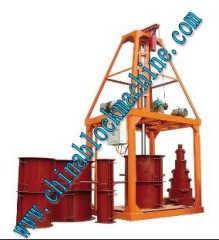

brick production line

block production line

automatic brick line

Siemens motor Ormon PLC

China well-known trademark

Brick production line, block machine plant, hollow block machine, solid block making machine, full-automatic baking-free brick machine, paver block machine, color brick machine, interlock block making machine, full-automatic curb stone block machine.

Brick production lineQT10-15 can produce various hollow block, solid bricks, color/paver blocks, and curb stone blocks, etc. This full-automatic block making machine adopts the table & mould vibration together: below the vibrating table, there are two vibrating boxes, and the two boxes are apart, so that they can send the vibration force to the vibrating table evenly; furthermore, there is another vibrating box on top of the upper mould. Thus, full-automatic block making machine QT10-15 can produce blocks with high density.

There are two hydraulic motors matched with QT10-15 full-automatic block making machine, and their vibration frequency can transform according to different work. This design will make the block have a good quality.

Brick production line QT10-15 uses international brand-name Germany Siemens motors and Japan Mitsubishi PLC, Japan Omron limit switch, reliable quality, low fault rate and durable. The material of whole frame is national standard steel, with high strength and reliable quality. All of its moulds are processed in high temperature, can work 80000-100000 times without losing shape.

Feeding system: this machine adopts 360°feeding system; it can finish feeding materials one time, saving much time, and ensures the density of blocks.

All our products have got ISO9001 and CE certification. The after sale service is one-up in our China.

Workshop area 250 square meters, need 6-8 workers, office, curing area, stacking are arranged according to the actual situation .

Production Efficiency:

Size (mm) Forming time Pcs/mould Pcs/h

Brick production lineQT10-15 can produce various hollow block, solid bricks, color/paver blocks, and curb stone blocks, etc. This full-automatic block making machine adopts the table & mould vibration together: below the vibrating table, there are two vibrating boxes, and the two boxes are apart, so that they can send the vibration force to the vibrating table evenly; furthermore, there is another vibrating box on top of the upper mould. Thus, full-automatic block making machine QT10-15 can produce blocks with high density.

There are two hydraulic motors matched with QT10-15 full-automatic block making machine, and their vibration frequency can transform according to different work. This design will make the block have a good quality.

Brick production line QT10-15 uses international brand-name Germany Siemens motors and Japan Mitsubishi PLC, Japan Omron limit switch, reliable quality, low fault rate and durable. The material of whole frame is national standard steel, with high strength and reliable quality. All of its moulds are processed in high temperature, can work 80000-100000 times without losing shape.

Feeding system: this machine adopts 360°feeding system; it can finish feeding materials one time, saving much time, and ensures the density of blocks.

All our products have got ISO9001 and CE certification. The after sale service is one-up in our China.

Workshop area 250 square meters, need 6-8 workers, office, curing area, stacking are arranged according to the actual situation .

Production Efficiency:

Size (mm) Forming time Pcs/mould Pcs/h

400*200*200 15-25s 10 1500-1800

400*250*200 15-25s 8 1200-1440

400*100*200 15-25s 20 3000-3000

240*115*90 15-25s 28 4000-6500

240*115*53 15-25s 54 7800-12500

200*100*60 15-25s 35 5000-8000

200*165*60 15-25s 20 2880-4800

225*112.5*60 15-25s 27 4050-4500

400*250*200 15-25s 8 1200-1440

400*100*200 15-25s 20 3000-3000

240*115*90 15-25s 28 4000-6500

240*115*53 15-25s 54 7800-12500

200*100*60 15-25s 35 5000-8000

200*165*60 15-25s 20 2880-4800

225*112.5*60 15-25s 27 4050-4500

The Main Technique Parameters:

Host machine dimension 3500*2220*2850 mm

Forming time 15-25s

Vibration form Table & mould vibration

Vibration frequency 2800-4500 r/min

Host machine power 40.1KW

Capacity 105KW

Vibration force 100KN

Mixer model JS750

Host machine weight 14T

Rated voltage 380V

Pallet size 1300*900*30mm

Water Consumption 12T/day

Forming time 15-25s

Vibration form Table & mould vibration

Vibration frequency 2800-4500 r/min

Host machine power 40.1KW

Capacity 105KW

Vibration force 100KN

Mixer model JS750

Host machine weight 14T

Rated voltage 380V

Pallet size 1300*900*30mm

Water Consumption 12T/day

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Production Line

Pipe Production Line

Cement Production Line

Beverage Production Line

Board Production Line

Foam Production Line

More>>